Khoom npe:polyurethane

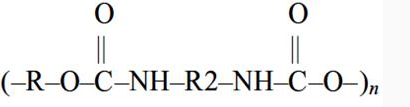

Cov khoom siv molecular:

Chemical Properties:

Polyurethane (PU), lub npe tag nrho ntawm polyurethane, yog cov khoom siv polymer. Xyoo 1937 los ntawm Otto Bayer thiab lwm yam khoom siv no. Muaj ob hom loj ntawm polyurethane, hom polyester thiab polyether hom. Lawv tuaj yeem ua rau hauv cov yas polyurethane (feem ntau ua npuas ncauj), polyurethane fibers (hu ua spandex hauv Suav teb), polyurethane roj hmab thiab elastomers.

Plexible polyurethane feem ntau yog cov qauv linear nrog thermoplasticity, uas muaj kev ruaj ntseg zoo dua, tshuaj lom neeg tsis kam, muaj zog thiab cov khoom siv kho tshuab dua li PVC ua npuas ncauj, nrog tsawg compression variability. Nws muaj zoo thermal rwb thaiv tsev, suab rwb thaiv tsev, poob siab tsis kam, thiab anti-toxic zog. Yog li ntawd, nws yog siv los ua ntim, suab rwb thaiv tsev thiab lim cov ntaub ntawv. Rigid polyurethane yas yog lub teeb, suab rwb thaiv tsev, superior thermal rwb thaiv tsev, tshuaj tiv thaiv, hluav taws xob zoo, kev ua haujlwm yooj yim, thiab nqus dej tsawg. Nws yog tsuas yog siv los ua cov khoom siv rau kev tsim kho, tsheb, kev lag luam aviation, rwb thaiv tsev kub thiab thermal rwb thaiv tsev. Polyurethane elastomer kev ua tau zoo ntawm cov yas thiab roj hmab, roj tsis kam, hnav tsis kam, kub tsis kam, kev laus ua haujlwm, siab hardness, elasticity. Nws yog tsuas yog siv hauv kev lag luam khau thiab kev kho mob kev lag luam. Polyurethane tuaj yeem ua rau cov nplaum, txheej, tawv hluavtaws, thiab lwm yam.

Daim ntawv thov:

Polyurethanes yog ib qho ntawm cov khoom siv ntau yam hauv ntiaj teb niaj hnub no. Lawv siv ntau yam los ntawm kev ua npuas ncauj yooj yim hauv cov rooj tog zaum hauv cov rooj tog zaum, kom ua npuas ncauj ua npuas dej hauv cov phab ntsa, ru tsev thiab cov khoom siv rau thermoplastic polyurethane siv hauv cov khoom siv kho mob thiab khau, rau coatings, adhesives, sealants thiab elastomers siv rau hauv pem teb thiab automotive interiors. Polyurethanes tau siv ntau zuj zus nyob rau peb caug xyoo dhau los hauv ntau daim ntawv thov vim lawv txoj kev nplij siab, cov txiaj ntsig zoo, txuag hluav taws xob thiab muaj peev xwm ib puag ncig zoo. Dab tsi yog qee yam ntawm cov khoom uas ua rau polyurethanes xav tau? Polyurethane durability pab txhawb rau lub neej ntev ntawm ntau yam khoom. Kev txuas ntxiv ntawm cov khoom lag luam lub neej thiab kev txuag cov peev txheej yog qhov tseem ceeb ntawm kev txiav txim siab ib puag ncig uas feem ntau nyiam xaiv cov polyurethanes[19-21]. Polyurethanes (PUs) sawv cev rau chav kawm tseem ceeb ntawm cov thermoplastic thiab thermoset polymers raws li lawv cov khoom siv hluav taws xob, thermal, thiab tshuaj lom neeg tuaj yeem raug kho los ntawm cov tshuaj tiv thaiv ntawm ntau yam polyols thiab poly-isocyanates.

Cov khoom qeb

-

Xov tooj

-

E-mail

-

Whatsapp

-

Sab saum toj