Vinyl acetate (VAc), tseem hu ua vinyl acetate lossis vinyl acetate, yog cov kua tsis muaj xim pob tshab ntawm qhov kub thiab txias, nrog cov mis molecular ntawm C4H6O2 thiab cov txheeb ze molecular hnyav ntawm 86.9. VAc, uas yog ib qho ntawm cov khoom siv organic ntau tshaj plaws hauv lub ntiaj teb, tuaj yeem tsim cov khoom siv xws li polyvinyl acetate resin (PVAc), polyvinyl cawv (PVA), thiab polyacrylonitrile (PAN) los ntawm tus kheej polymerization lossis copolymerization nrog lwm cov monomers. Cov derivatives no tau siv dav hauv kev tsim kho, textiles, machinery, tshuaj, thiab av txhim kho. Vim muaj kev loj hlob sai ntawm kev lag luam davhlau ya nyob twg nyob rau hauv xyoo tas los no, kev tsim cov yas acetate tau pom ib qho kev nce xyoo los ntawm lub xyoo, nrog rau tag nrho cov khoom siv vinyl acetate nce mus txog 1970kt hauv 2018. Tam sim no, vim muaj kev cuam tshuam ntawm cov khoom siv raw thiab cov txheej txheem, cov txheej txheem ntau lawm ntawm vinyl acetate feem ntau suav nrog txoj kev aceethylenene.

1 、 Cov txheej txheem acetylene

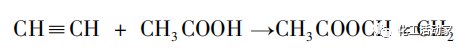

Xyoo 1912, F. Klatte, ib tug neeg Canadian, thawj zaug pom vinyl acetate siv ntau tshaj acetylene thiab acetic acid nyob rau hauv atmospheric siab, ntawm qhov kub ntawm 60 mus rau 100 ℃, thiab siv mercury ntsev ua catalysts. Xyoo 1921, Lub Tuam Txhab German CEI tau tsim cov thev naus laus zis rau vapor theem synthesis ntawm vinyl acetate los ntawm acetylene thiab acetic acid. Txij thaum ntawd los, cov kws tshawb fawb los ntawm ntau lub teb chaws tau txuas ntxiv txhim kho cov txheej txheem thiab cov xwm txheej rau kev sib txuas ntawm vinyl acetate los ntawm acetylene. Xyoo 1928, Hoechst Tuam Txhab ntawm Lub Tebchaws Yelemees tau tsim 12 kt / vinyl acetate ntau lawm chav tsev, paub txog kev lag luam loj loj ntawm cov yas acetate. Qhov sib npaug ntawm kev tsim cov yas acetate los ntawm txoj kev acetylene yog raws li nram no:

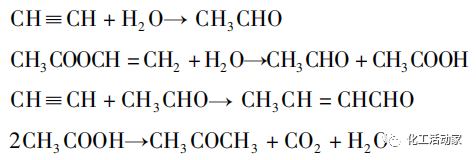

Cov tshuaj tiv thaiv tseem ceeb:

Txoj kev Acetylene muab faib ua kua theem txoj kev thiab roj theem txoj kev.

Lub reactant theem lub xeev ntawm acetylene kua theem txoj kev yog kua, thiab lub reactor yog ib tug tshuaj tiv thaiv tank nrog ib tug stirring ntaus ntawv. Vim qhov tsis zoo ntawm cov txheej txheem ua kua theem xws li kev xaiv qis thiab ntau cov khoom lag luam, cov qauv no tau hloov los ntawm acetylene roj theem txoj kev tam sim no.

Raws li qhov sib txawv ntawm acetylene gas npaj, acetylene roj theem txoj kev yuav muab faib ua natural gas acetylene Borden method thiab carbide acetylene Wacker method.

Cov txheej txheem Borden siv acetic acid raws li ib tug adsorbent, uas zoo heev txhim kho tus nqi ntawm acetylene. Txawm li cas los xij, txoj hauv kev no yog technically nyuaj thiab yuav tsum tau them nqi siab, yog li txoj kev no muaj txiaj ntsig zoo hauv thaj chaw nplua nuj ntawm cov khoom siv roj av.

Cov txheej txheem Wacker siv acetylene thiab acetic acid uas tsim los ntawm calcium carbide ua raw cov ntaub ntawv, siv lub catalyst nrog activated carbon li carrier thiab zinc acetate ua active tivthaiv, los ua ke VAc nyob rau hauv atmospheric siab thiab cov tshuaj tiv thaiv kub ntawm 170 ~ 230 ℃. Cov txheej txheem thev naus laus zis yog qhov yooj yim thiab muaj cov nqi tsim khoom tsawg, tab sis muaj qhov tsis zoo xws li kev poob yooj yim ntawm cov khoom siv catalyst, tsis muaj kev ruaj ntseg, kev siv hluav taws xob ntau, thiab cov pa phem loj.

2, Ethylene txheej txheem

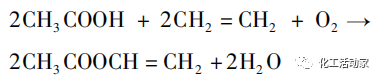

Ethylene, oxygen, thiab glacial acetic acid yog peb cov khoom siv raw siv hauv ethylene synthesis ntawm vinyl acetate txheej txheem. Lub ntsiab active tivthaiv ntawm lub catalyst yog feem ntau yim pab pawg neeg noble hlau, uas yog reacted ntawm ib tug tej yam tshuaj tiv thaiv kub thiab siab. Tom qab ua tiav tom qab, lub hom phiaj khoom vinyl acetate yog thaum kawg tau. Qhov sib npaug ntawm cov tshuaj tiv thaiv yog raws li nram no:

Cov tshuaj tiv thaiv tseem ceeb:

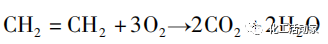

Kev mob tshwm sim:

Cov txheej txheem ethylene vapor theem yog thawj zaug tsim los ntawm Bayer Corporation thiab tau muab tso rau hauv kev tsim khoom rau kev tsim cov yas acetate hauv xyoo 1968. Cov kab ntau lawm tau tsim nyob rau hauv Hearst thiab Bayer Corporation hauv lub teb chaws Yelemees thiab National Distillers Corporation hauv Tebchaws Meskas, feem. Nws yog tsuas yog palladium los yog kub loaded ntawm cov kua qaub resistant, xws li silica gel hlaws dai nrog ib lub vojvoog ntawm 4-5 hli, thiab ntxiv ib co ntawm cov poov tshuaj acetate, uas yuav txhim kho cov kev ua thiab xaiv ntawm cov catalyst. Cov txheej txheem rau kev sib txuas ntawm vinyl acetate siv ethylene vapor theem USI txoj kev zoo ib yam li Bayer txoj kev, thiab muab faib ua ob ntu: synthesis thiab distillation. Cov txheej txheem USI tau ua tiav daim ntawv thov kev lag luam hauv xyoo 1969. Cov khoom siv ntawm cov catalyst feem ntau yog palladium thiab platinum, thiab tus neeg sawv cev pabcuam yog potassium acetate, uas yog txhawb nqa ntawm alumina carrier. Cov kev mob tshwm sim kuj yog me ntsis thiab cov catalyst muaj lub neej ntev kev pab cuam, tab sis qhov chaw-lub sij hawm tawm los yog tsawg. Piv nrog rau txoj kev acetylene, ethylene vapor theem txoj kev tau zoo heev nyob rau hauv technology, thiab cov catalysts siv nyob rau hauv txoj kev ethylene tau tsis tu ncua kev txhim kho nyob rau hauv kev ua si thiab xaiv. Txawm li cas los xij, cov tshuaj tiv thaiv kinetics thiab deactivation mechanism tseem yuav tsum tau tshawb nrhiav.

Kev tsim cov yas acetate siv txoj kev ethylene siv cov tubular tsau txaj reactor uas muaj cov catalyst. Cov pa roj nkag mus rau hauv lub reactor los ntawm sab saum toj, thiab thaum nws hu rau lub catalyst txaj, catalytic tshua tshwm sim los tsim lub hom phiaj khoom vinyl acetate thiab ib tug me me ntawm cov khoom los ntawm carbon dioxide. Vim lub exothermic xwm ntawm cov tshuaj tiv thaiv, cov dej pressurized yog nkag mus rau hauv lub plhaub sab ntawm lub reactor kom tshem tawm cov tshuaj tiv thaiv tshav kub los ntawm kev siv lub vaporization ntawm dej.

Piv nrog rau txoj kev acetylene, txoj kev ethylene muaj cov yam ntxwv ntawm cov khoom siv compact, cov khoom siv loj, kev siv hluav taws xob tsawg, thiab tsis muaj kuab paug, thiab nws cov nqi khoom qis dua li ntawm txoj kev acetylene. Cov khoom zoo yog superior, thiab qhov teeb meem corrosion tsis loj. Yog li ntawd, txoj kev ethylene maj mam hloov txoj kev acetylene tom qab xyoo 1970s. Raws li kev txheeb cais tsis tiav, kwv yees li 70% ntawm VAc tsim los ntawm txoj kev ethylene hauv ntiaj teb tau dhau los ua qhov tseem ceeb ntawm VAc ntau lawm txoj kev.

Tam sim no, VAc ntau lawm technology nyob rau hauv lub ntiaj teb no yog BP's Leap Process thiab Celanese's Vantage Process. Piv nrog rau cov txheej txheem ethylene kho lub txaj ib txwm siv, ob txoj kev thev naus laus zis no tau txhim kho cov reactor thiab catalyst ntawm lub hauv paus ntawm chav tsev, txhim kho kev lag luam thiab kev nyab xeeb ntawm chav ua haujlwm.

Celanese tau tsim ib lub txaj tshiab Vantage txheej txheem los daws cov teeb meem ntawm qhov tsis sib xws catalyst txaj faib thiab qis ethylene ib-txoj kev hloov dua siab tshiab rau hauv lub txaj ruaj khov reactors. Lub reactor siv hauv cov txheej txheem no tseem yog lub txaj ruaj khov, tab sis kev txhim kho tseem ceeb tau ua rau lub zog catalyst, thiab cov khoom siv rov qab ethylene tau ntxiv rau hauv cov roj av, kov yeej cov kev tsis txaus ntawm cov txheej txheem hauv txaj. Cov txiaj ntsig ntawm cov khoom yas acetate yog qhov siab dua li cov khoom siv zoo sib xws. Cov txheej txheem catalyst siv platinum ua lub ntsiab active tivthaiv, silica gel raws li catalyst carrier, sodium citrate raws li ib tug txo tus neeg sawv cev, thiab lwm yam auxiliary hlau xws li lanthanide tsawg lub ntiaj teb cov ntsiab lus xws li praseodymium thiab neodymium. Piv nrog rau cov catalysts ib txwm muaj, qhov kev xaiv, kev ua, thiab qhov chaw-lub sij hawm tawm los ntawm cov catalyst tau txhim kho.

BP Amoco tau tsim cov txheej txheem fluidized txaj ethylene gas theem, tseem hu ua Leap Process txheej txheem, thiab tau tsim 250 kt / ib chav pw fluidized hauv Hull, England. Kev siv cov txheej txheem no los tsim cov yas acetate tuaj yeem txo cov nqi tsim khoom los ntawm 30%, thiab qhov chaw lub sij hawm tawm los ntawm cov catalyst (1858-2744 g / (L · h-1)) yog ntau dua li cov txheej txheem txaj ruaj (700-1200 g / (L · h-1)).

Cov txheej txheem LeapProcess siv lub txaj fluidized reactor thawj zaug, uas muaj qhov zoo hauv qab no piv rau lub txaj ruaj khov reactor:

1) Nyob rau hauv ib tug fluidized txaj reactor, lub catalyst yog tsis tu ncua thiab uniformly tov, yog li pab mus rau lub uniform diffusion ntawm tus txhawb thiab kom ntseeg tau ib tug uniform concentration ntawm tus txhawb nyob rau hauv lub reactor.

2) Lub txaj fluidized reactor tuaj yeem hloov pauv cov deactivated catalyst nrog cov catalyst tshiab hauv kev ua haujlwm.

3) Lub fluidized txaj cov tshuaj tiv thaiv qhov kub thiab txias yog qhov tsis tu ncua, txo qis catalyst deactivation vim qhov cua sov hauv zos, yog li ncua kev pab cuam lub neej ntawm cov catalyst.

4) Txoj kev tshem tawm cua sov siv nyob rau hauv lub txaj fluidized reactor simplifies lub reactor qauv thiab txo nws ntim. Hauv lwm lo lus, ib qho kev tsim hluav taws xob nkaus xwb tuaj yeem siv rau kev teeb tsa tshuaj lom neeg loj, ua kom muaj txiaj ntsig zoo ntawm cov cuab yeej.

Post lub sij hawm: Mar-17-2023